This time there is also a short video accompanying the blog post, so if you are inclined, it has a few more visuals of the machine. But we only started filming in the middle of the endever, so we still need work on our videography skills.

As luck would have it, our unhealthy—but undeniably fruitful—addiction to Kleinanzeigen (German Craigslist for the mechanically deranged) paid off again. We stumbled across a Hardinge HTC lathe with a mountain of accessories and a price tag that basically whispered: “I’m broken, please rescue me.”

Naturally, we did what any rational person would do: we bought it.

By now, we’ve gained a questionable amount of experience unloading heavy machines from a car trailer, but it’s still a spectacle every time. This round we went with the classic: stack some pallets behind the trailer, drag the machine onto them, and lower it down like two very determined forklifts… without a forklift.

Ok, now that we had the machine in a appropiarte working height we needed to do an assessment of the current state of the machine. So there were quite a few issues:

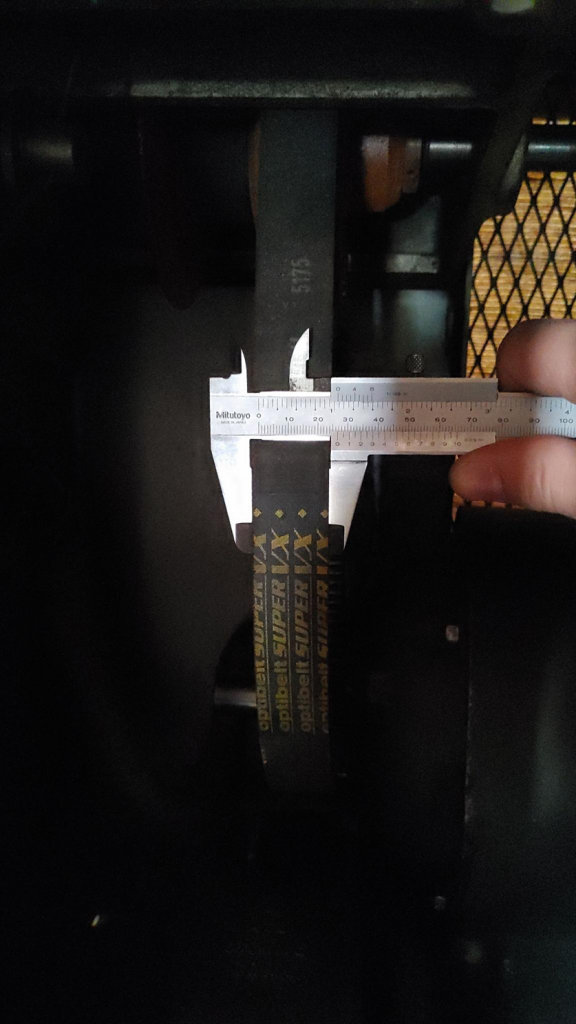

- The motor-to-Variomat pulley was broken (someone had tried to pull it off by force… not us, this time).

- The motor only ran while you held the start button down.

- The motor only ran backwards. Not forward. Because why would it?

- The cross slide only moved a few centimeters.

- The electric power feed for the carriage was dead.So, time to get fixing the problems.

First step was fixing the pulley:

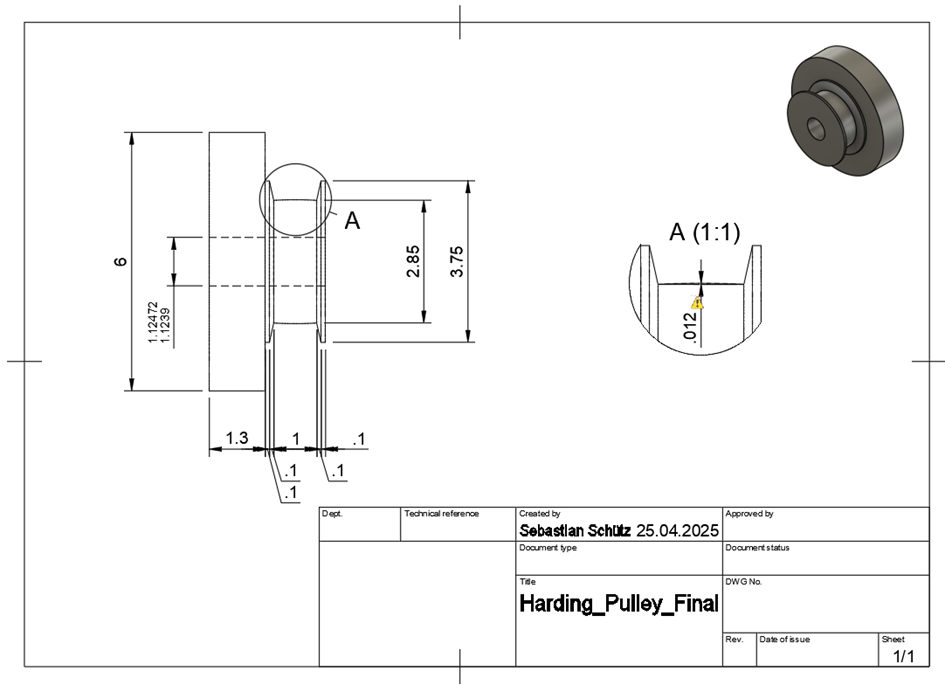

We took some carefull meassurements and then decided to make a drawing (sadly in inch), where we approximated the meassurements as far as possible

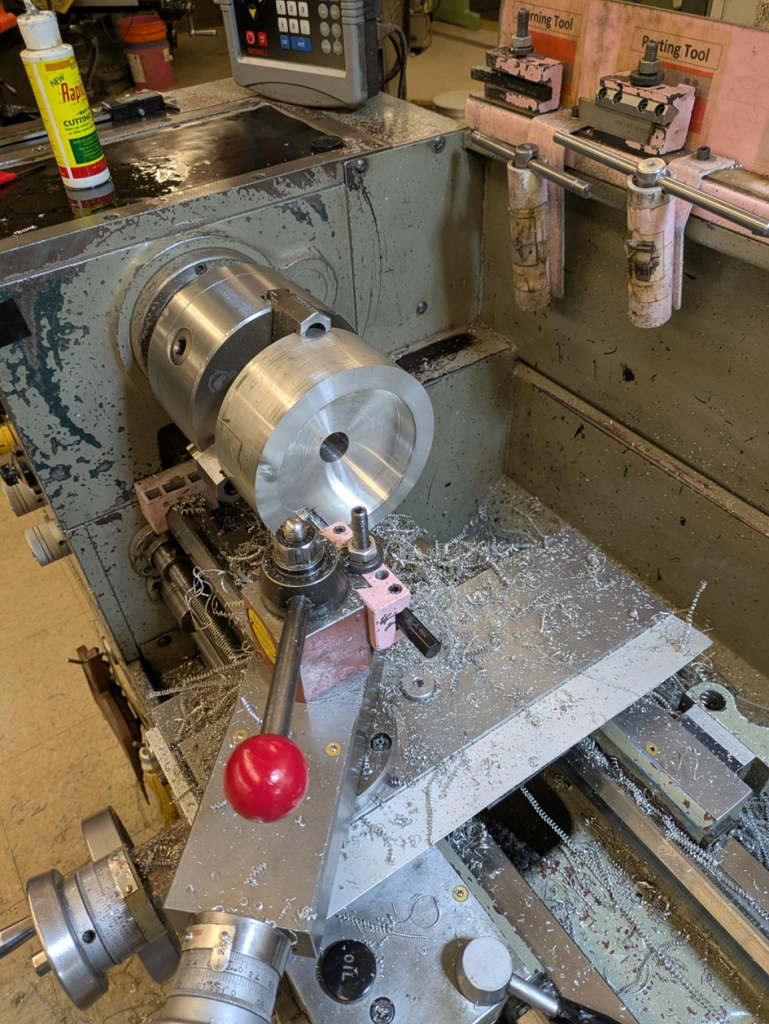

As one can see, we only added tolerances for the bore in the middle, as the rest is technically not that critically. We decided to replicate the original pulley, designed for a flatbelt as close as possible. Thankfully Sebastian was in the US at that moment and had access to the machine shop of the University. So we turned a lot of aluminium into chips:

SO, the keen eyed already saw, that this is aluminium… This is not a perfect material for pulleys. And you are correct. But there were two concerns:

- Weight: Sebastian needed to bring this back with his stuff on the airplane. And in we end we already maxed out out weight limits, so thank god we choose aluminium

- Secondly, We want to see how the pulley performs, because the current installed belt is not the original one. So we figured, we try it now, and then if the performance degrades too much, we can still make it out of steel, but this time around we already have a lathe we can use…

And if you wonder, how we got the keyway in: Sebastian just ground a HSS-Blank, mounted it in the lathe and then used the lathe as a shaper, slowly pushing the material out of the way

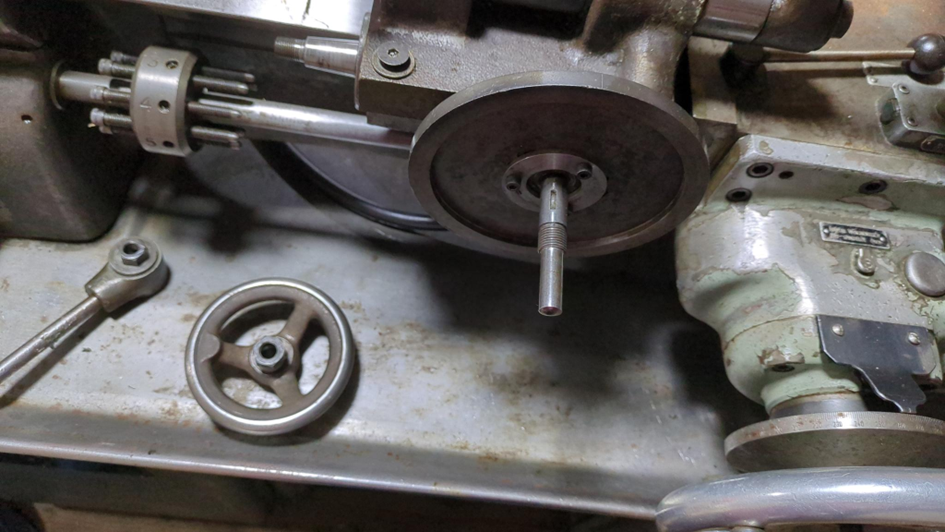

You’d think putting on a pulley with a standard keyway would be trivial. It was not.

Hardinge used an 8 mm key, but for some reason ignored standard keyway depth. It was too shallow. So we filed the key down until it fit. Not our proudest moment, but effective.

Then we discovered the pulley was too short for the original tensioning method. The adjusting stud was so worn that the threads were not gripping anymore. So we replaced it with a piece of M12 threaded rod. Problem solved

Electric Wiring

So, the first part was the motor, only running, while the start button was being pushed. This was an pretty easy fix, we just needed to rewire the contactor to a latching circuit and then it worked like a charm. Figuring out the motor running in only one direction was actually also not too bad. Because it spins in one direction but not the other, we were pretty confident, that the motor in itself is fine. As it is a three phase motor, switching directions is as easy as switching two phases. So we postulated, that it must be an error with the switching of the phases. Turns out, the contactor, that mechanically switched the phases did not make fully contact in the forward configuration, so only two of the three phases were connected.

Cross Slide only moves a few cms

This one actually gave us some trouble. In the end there were more problems as always, like a missing woodruff key, but long story short: This lathe has two ways of how one can move the cross slide. Either by using a leadscrew, or by using a lever. Problem was, as far as we understood the mechanism, that the lever is supposed to be removeable, but would not budge. So it was limiting out range of motion. In the end some heat and a bearing puller helped to free the stuck lever and now we can use the cross slide as well.

Electric Power feed:

- Initially we had hoped, that it would only be a wiring issue, but it seems to be something more severe. But actually I am not to keen on spending more time debugging this issue, because this machine does not have a normal lead screw for thread cutting, but a special thread cutting attachment

- So I am thinking of removing the original motor and exchanging it for a stepper so, that on can have an electric lead screw, because we still need a DRO

Ok, so what is next?

So the machine is now in working condition, which is quite nice, but at the end of the day, is a machine ever really finished? We already have a lot of things we still need and want to do with this machine:

- Add a dial to the cross slide for better readability

- Add a DRO (and maybe a spindle encoder and a stepper for a electric lead screw)

- Find a tailstock